Choosing the right metal fabricator is critical for ensuring your needs are being met, particularly those around quality, cost, and delivery. Most companies that write blogs on choosing a manufacturing partner use the positive aspects of their company to create the list. Of course, it’s not a coincidence that what they say you “must have” is precisely what they offer. It’s akin to people showing the world snapshots of only their filtered, positive, and best features on social media. In this post, we are taking the filter off and letting you in on a secret: We might not be right for you, and you might not be right for us. And that’s OK. But there’s also the possibility that we’re a perfect fit for each other, allowing us to reap the benefits of a strong partnership.

A Manufacturing Partner That Will “Go For The No”

You might be shocked to learn that we would say no to a prospect. It sounds counterintuitive to good business practice. But when you understand why, you will see that it benefits our clients.

“Go for the no” is a Sandler sales technique emphasizing qualifying buyers (or sellers) rather than persuading them to buy. Uncovering reasons for you to say no to us, or conversely, us to say no to you, saves us all time and resources. Resources are limited, and we prefer that you use them in a way that will benefit your company. It allows us to efficiently focus on our clients to provide the best service and products possible. We have all had clients that take a lot of resources and bring little value to the partnership because we are trying to make them fit. It’s a lose-lose situation.

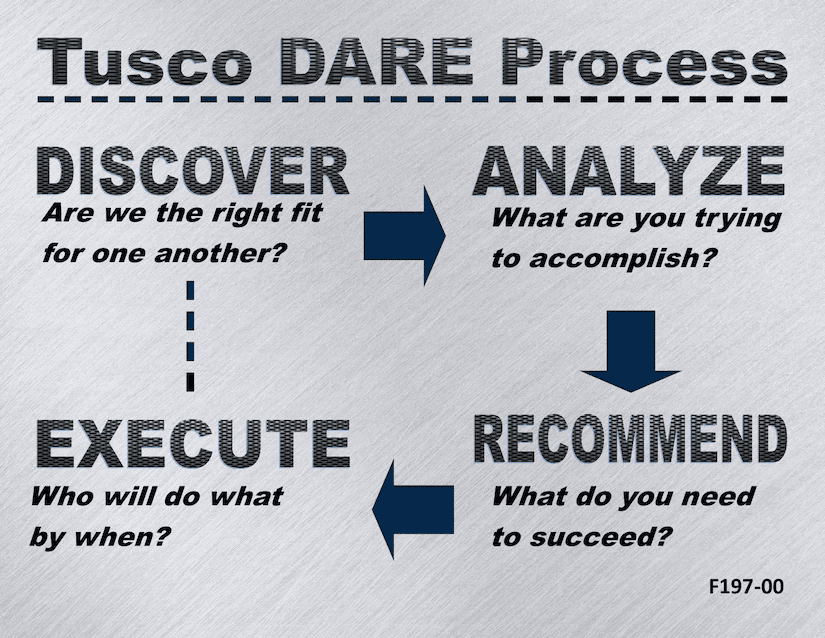

We have a process called DARE that allows us to focus on our prospect’s needs to ensure we are a good fit. If we are a good fit, we want to ensure we execute the plan together as partners. We also use this for our vendors, so this is a process that you can use to evaluate all your potential manufacturing partners and other vendors.

How the DARE Process Works

DARE stands for discover, analyze, recommend, and execute. This process allows us to meet your expectations by asking the right questions early on. We want to ensure that we can deliver to your expectations. Sometimes, for assorted reasons, we can’t. We have been in the industry for a long time and know many of our competitors and where their strengths are, so if you are not a fit for us, we will tell you why and who we think may help you. We use the DARE process to become a working extension of your team to ensure you get the best cost, turnaround time, and quality solution–whether from us or someone else!

Discover

Our discovery meeting is the most important. We ask questions to understand your needs regarding materials, processes, volumes, timing, and payment terms. For example, concerning volumes, we can make hundreds of parts or thousands of parts, but hundreds of thousands of parts require high-speed production, like stamping, not fabrication, and tens of parts raise costs considerably. Similarly, with timing, we will let you know if turnaround times can be reasonably met based on what needs to be done and delivered to make it a reality. We prefer to under-promise and over-deliver than to make a promise we can’t keep and leave you disappointed.

Analyze

During the analyze phase, we dig deeper beyond costs and timelines. We want to understand what about this project has kept you up at night or what are some of the challenges you have faced. We will dig into details, such as your goals, how the product will be used, and how we will know we have been successful. We ask candid questions about what you want to accomplish. It could be a current vendor isn’t communicating, costs are too high, or something else is causing pain. These are the things we want to know as they allow us to create a better experience for you. We want you to ask us questions, too. We put ourselves in your shoes and ask if we were you, would we recommend TuscoMFG for this partnership?

Recommend

During this phase, we demonstrate the benefits of value engineering. We evaluate your project and recommend ways to reduce costs (parts, materials, maintenance, labor, etc.) while maintaining part quality, safety, and functionality. For example, our engineers may look at your product and determine that using a channel would be more cost-effective than tubing, or they may look at downstream impacts and determine that components can be designed to reduce assembly labor or make maintenance easier. Of course, we understand that sometimes, there are legitimate reasons for a part being designed in a certain way, but through open communication, we can ensure your product meets your needs in every way.

Execute

In this last phase, we determine who will do what when. We lay out the plan of what activities need to be done by both parties to accomplish the project’s goals. Some of those requirements might be to execute a nondisclosure agreement, provide us with prints and samples, do a redesign, approve the redesign, prototype, create any tooling, and then develop a production order we will execute against. It is essential that we commit to one another and understand who is responsible for what and when it is needed.

We are accustomed to thinking systematically about how we take on and execute new projects. If there is a problem, we will communicate it to you immediately. Our systematic approach keeps projects running efficiently and orders delivered on time. We objectively deliver on time across thousands and thousands of shipments 97 percent of the time.

If you are ready to work with a partner that values your time and resources and is dedicated to delivering high-quality, cost-effective sheet metal products on time, contact us to discuss your project.