Wire forming transforms rolls of wires into useful finished product. Straightening, cutting, forming, and resistance welding of single wire, wire frame, and assemblies or complex grids have all become core competencies at Tusco.

With manufacturing experience comes not just the ability to deliver results according to project specifications, but also the knowledge to ask for the details that will ensure the job gets done well with minimal waste and cost.

We inventory bulk, bright basic, carbon steel wire from 12ga. to 5/16″ in diameter, which we fabricate with a wide range of available forming processes.

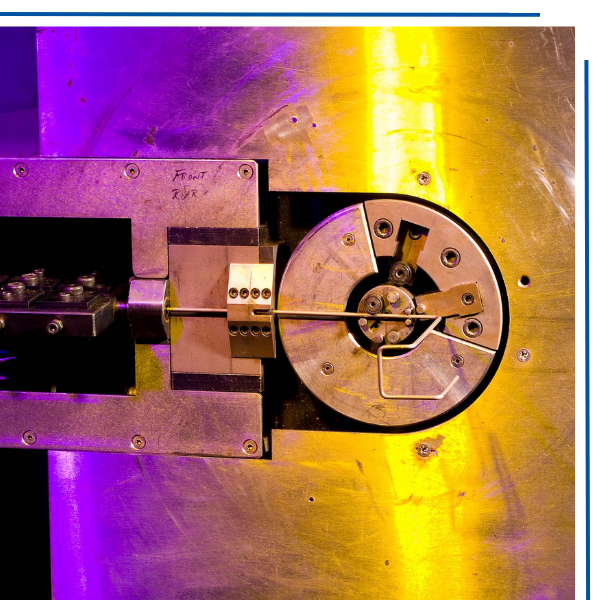

With our wire forming, we can produce intricate wire components quickly and without tooling costs. Normally, these associated charges can quickly drive up project costs, which is why it’s so critical to develop streamlined processes before commencing a project. We use our AIM Model AFM3D1-TUF machine, which is a high-speed, CNC-controlled, 3-dimensional wire former. This model gives us maximum control over the finished product and machine maintenance, which ensures that raw materials are handled with care and precision.

We employ rocker arm welders, press welders, and three separate CNC-controlled resistance welding cells. Using machinery and tools regularly and consistently elevates the control we have over the quality of the finished product. For you, this means that we can meet your specifications easily, quickly, and at lower costs.

Our solutions are tailored specifically to your project.

Custom laser cutting with our Trumpf Trulaser 5030 laser.

Varied brake presses provide the perfect form.

Fabricated tube assemblies are custom formed and joined.

Certified MIG and TIG welders are supplemented by robotic welders.

Powder coating protects your product and sets it apart from the competition.

Woodworking solutions create one-of-a kind, mixed-media projects.

Custom cut, shaped, or fabricated plastic components provide mixed-media dimension.

Our on-site warehouse is available to allow us to directly drop ship your project anywhere.

Everything from screenprinting to packaging can be done before shipping your project out.