Full-Service Precision Sheet Metal Fabricator

Original equipment manufacturers (OEM) buying fabricated assemblies can have very complex design requirements. Customer demand becomes more sophisticated every year. Each OEM seeks a cost-effective, competitive edge without sacrificing performance, quality, or on-time delivery.

Do you know if your vendor partner has the in-house ability to make your part on time and complete-to-print? One-stop shopping can deliver peace of mind. Vendors with a beginning-to-end capability to make fabricated assemblies can deliver the speed and reliability you need.

The Tusco engineering team assists our clients in design and DFM (Design For Manufacturing) improvements with an intimate understanding of every step of the process, because we do it all in-house. This in-depth understanding enables us to be much more flexible, quicker, and more reliable than the average fabricator.

Innovations in precision sheet-metal fabrications are also born from experimentation with in-house capabilities. Each new project requires unique combinations of abilities to solve the design challenges. When you are unsure of the answer, we can push the limits by testing the innovative theory on our own equipment. If we aren’t completely confident in our ability to deliver, we will test until we know we are.

Precision sheet-metal fabricators with total in-house capabilities reduce your risk of poor quality. We can limit the total handling of your parts. Our fabrication processes involve many pieces of equipment that are mobile with quick disconnect to create instant work cells around key work centers. The further your part travels, the higher the chance there will be of scratches, dings, and dents.

Our solutions are tailored specifically to your project.

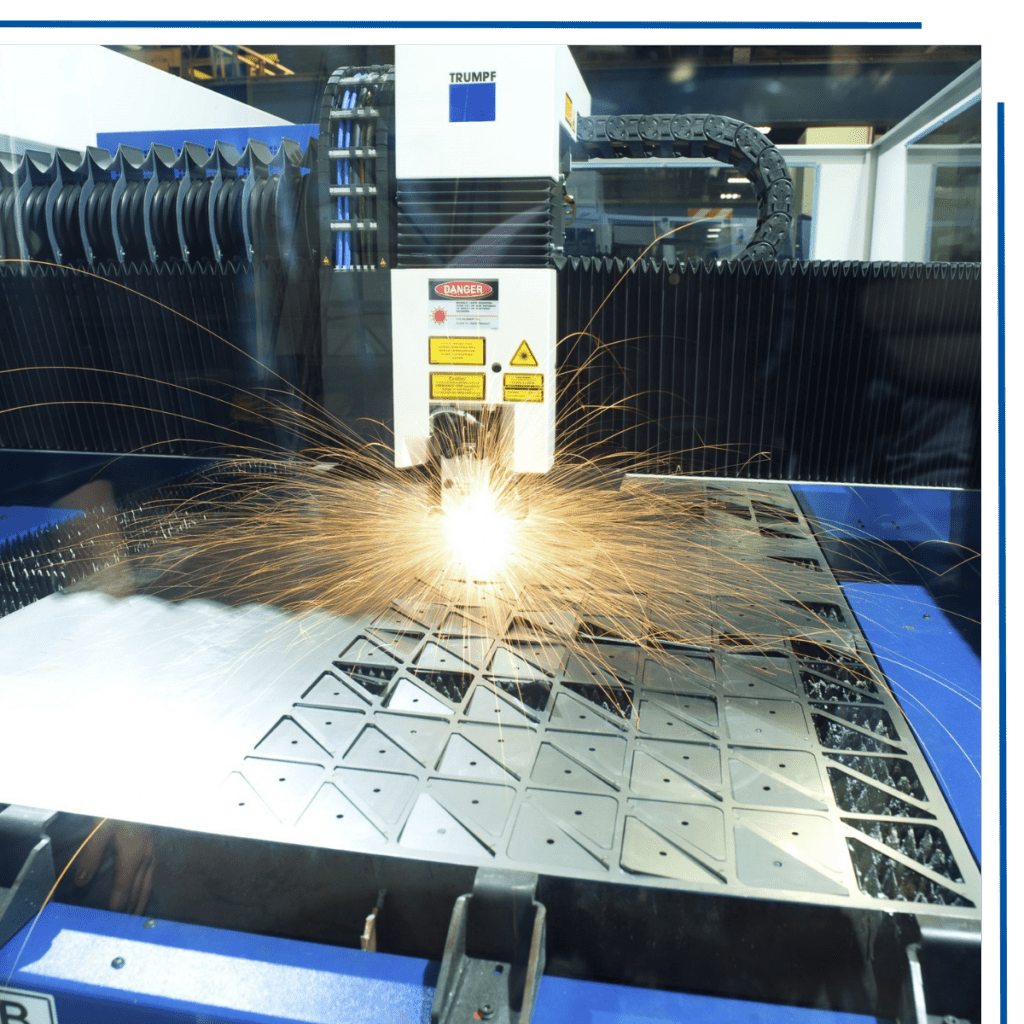

Custom laser cutting with our Trumpf Trulaser 5030 laser.

Varied brake presses provide the perfect form.

Fabricated tube assemblies are custom formed and joined.

We produce intricate wire components quickly and without tooling costs.

Certified MIG and TIG welders are supplemented by robotic welders.

Powder coating protects your product and sets it apart from the competition.

Woodworking solutions create one-of-a kind, mixed-media projects.

Custom cut, shaped, or fabricated plastic components provide mixed-media dimension.

Our on-site warehouse is available to allow us to directly drop ship your project anywhere.

Everything from screenprinting to packaging can be done before shipping your project out.