The fine powder used in this process combines polymer resin with pigment, leveling agents, curatives, and other additives designed to reinforce the coating when it is applied to the intended surface.

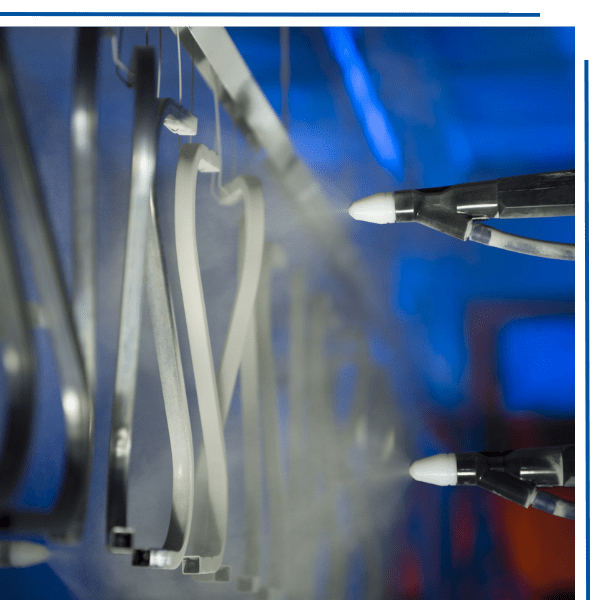

This durable, efficient finish is electrostatically applied with spray guns to ensure an even coating and then baked in a gas-fired curing oven. The application of heat at the end of the process facilitates the creation of long molecular chains with high cross-link density that effectively “sets” the coating in place.

The types of wear and tear that powder coating can resist are varied. Just as your fabrications are custom to your needs, we choose the right coating for your specific applications. This capability fits naturally into Tusco’s mission to remain nimble and easily adapt to your project’s needs. The conditions that powder coating can address include prolonged contact with harsh chemicals, impact, ultraviolet light, moisture, and other extreme conditions.

Powder coating is both durable and eye-catching, which combines practicality with aesthetic appeal. Custom colors can be readily produced as long as a five-gallon or 50-pound minimum is met.

The specific features of resistance can be customized for each powder coating formulation. This saves you money over the life of your fabrication and reduces the incidence of wear issues like fading, chipping, abrasions, and corrosion. Overall, this process extends the life of your project.

Beyond powder coating, we offer plating options including chrome and zinc plating. Both of these processes produce surface barriers to prevent corrosion and are provided by supply chain partners who meet our quality and environmental standards.

Our solutions are tailored specifically to your project.

Custom laser cutting with our Trumpf Trulaser 5030 laser.

Varied brake presses provide the perfect form.

Fabricated tube assemblies are custom formed and joined.

We produce intricate wire components quickly and without tooling costs.

Certified MIG and TIG welders are supplemented by robotic welders.

Woodworking solutions create one-of-a kind, mixed-media projects.

Custom cut, shaped, or fabricated plastic components provide mixed-media dimension.

Our on-site warehouse is available to allow us to directly drop ship your project anywhere.

Everything from screenprinting to packaging can be done before shipping your project out.