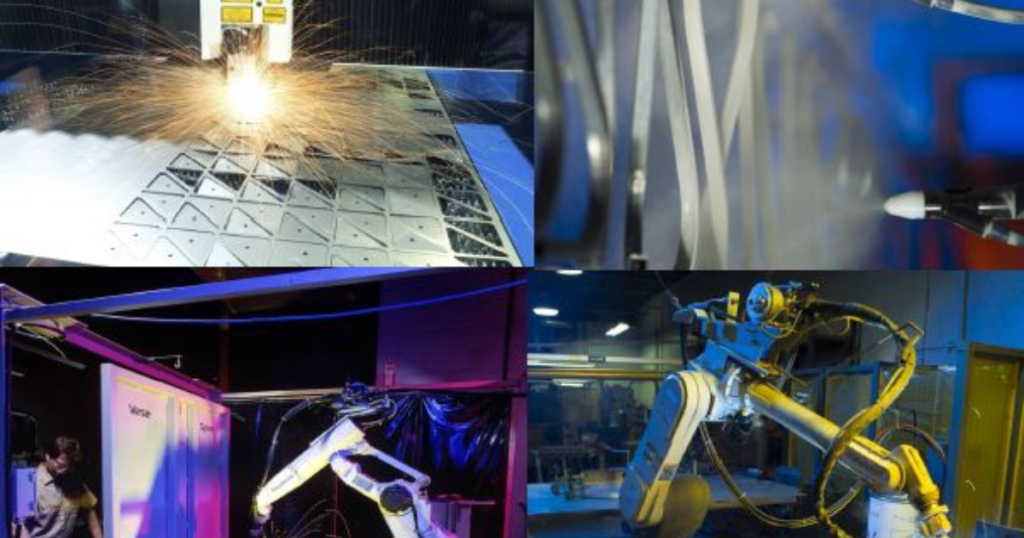

Project management in metal fabrication, whether a retail display or custom component, is crucial for delivering high-quality products on time. At TuscoMFG, every project is unique and requires its own plan. We provide every customer with a dedicated point of contact from the client services team, who provides leadership to keep the project on track. This team member is always ready to answer questions while they ensure the program is running smoothly. In this post, we will outline critical components of Tusco’s approach to project management.

What is Project Management?

Project management is the process of initiating, planning, executing, and monitoring a project to achieve specific goals and objectives within a defined scope, time, and budget. There are many steps in metal manufacturing – discovery call, quoting, engineering, manufacturing and secondary operations, assembly, packaging, shipping, billing – and many people involved. Without a project management plan, the process could break down at any of those steps. We appoint a client services team member to manage the project, communicate with various teams, and ensure the customer is satisfied. Project management is essential to our business, providing consistent quality, timely delivery, and unrivaled customer satisfaction.

Initiation

The discovery call is our initial contact with a customer, where we define the project scope by learning their needs, budget, and timeline for delivery. We evaluate the project and ask questions to ensure we are a good fit: Can we meet the tolerances? Are the volumes appropriate? Is the timeline reasonable? We do not take on every project, but if we turn down a project, in most situations, we will recommend a vendor that may be able to help them.

Planning

Planning is a critical component of project management as it sets the foundation for the project. It includes work breakdown structure, resource allocation, and establishing a timeline.

In project management, a work breakdown structure simply details the project, including acceptance criteria (e.g., standards or customer requirements), budget, and deliverables or project phases (e.g., prototype, manufacturing). It defines the project and may include specific boundaries of what is outside the scope.

The project cost is estimated from drawings or concepts provided or created based on initial discussions. The client services team member ensures the resources are in place by coordinating with purchasing and operations, and an estimated timeline can be developed. Depending on the project, the timeline may include prototype (or first article), production, and shipping. Displays will also include concepts prior to the prototype being developed. Timely customer approvals are critical for keeping the project on track.

Execution Monitoring

The heart of a program is its execution. While the client services team member isn’t directly involved in creating the prototype or manufacturing the product, they do closely monitor the program’s progress. Communication and risk management are critical facets of executing a successful project.

Risk management is one of the values received from working with a company that implements a project management strategy. The team will identify potential bottlenecks or disruptions in the supply chain and communicate them to the customer when appropriate. In some cases, we might develop backup plans to handle unexpected issues.

A key to this is communication and transparency. In the event of an unforeseen challenge, input from several stakeholders may be required. The client services team member will communicate internally between teams and with the customer to ensure everyone is on the same page and a solution can be worked out.

The client services team member will also monitor the project’s quality control outcomes and other KPIs to gauge the project’s health and communicate any challenges. They will also manage any changes to the project to ensure they are effectively communicated to all involved parties.

Closure

At the project’s close, the client services team member will ensure the deliverables have been met. Records and documentation will be kept for future reference. A post-project evaluation may be conducted to identify successes and areas for improvement.

By instituting a project management strategy, we have better control over resource utilization, risk mitigation, and quality control, leading to successful project completion.

Contact us for your next sheet metal project and let us show you the Tusco difference.